Ultimate Ductwork Guide: Optimize Your HVAC for Maximum Efficiency

-

By

Michael Haines

By

Michael Haines

- Feb 7, 2024

Ultimate Ductwork Guide: Optimize Your HVAC for Maximum Efficiency

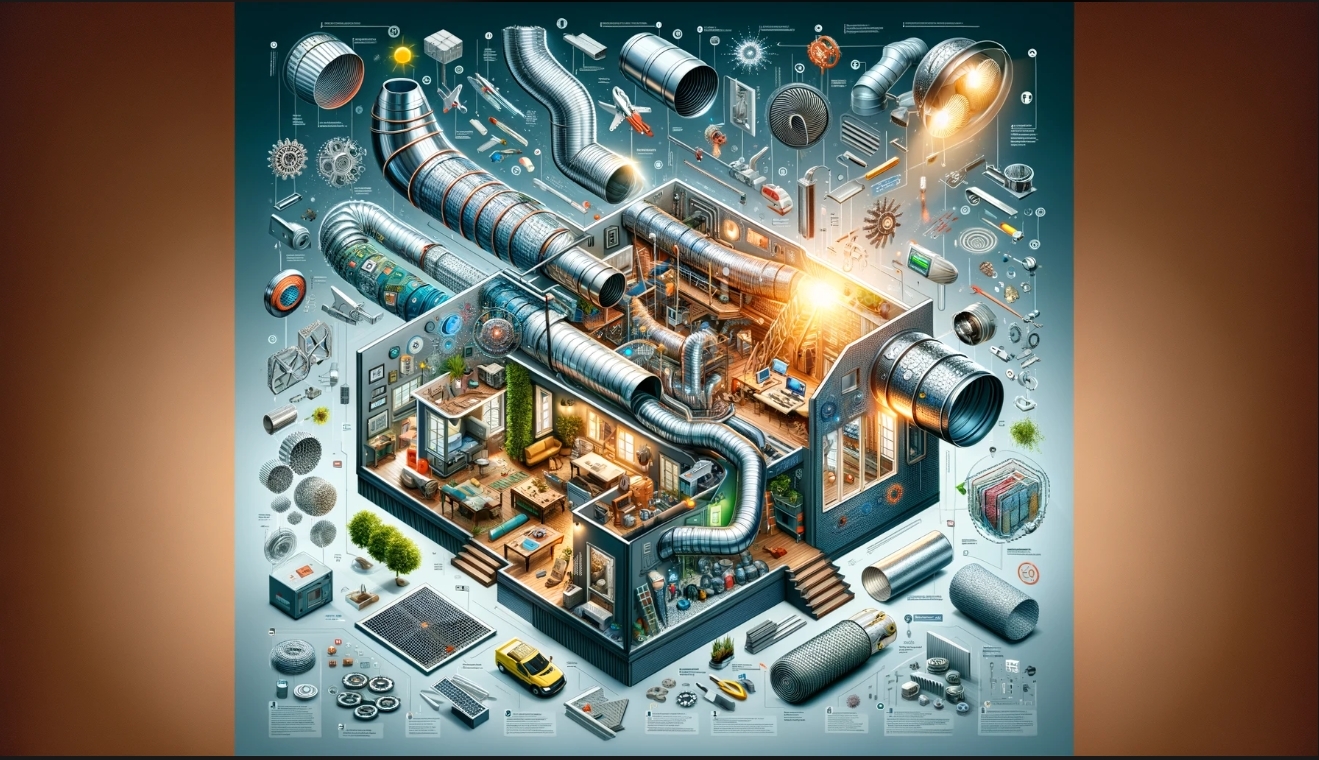

Written by Michael Haines 02/07/2024 Hey there! Let's talk about something that's crucial in your home but often overlooked: ductwork. It's the backbone of your HVAC system, ensuring that air flows where it's needed, keeping you cozy in winter and cool in summer. Without well-designed ductwork, your air conditioner and furnace might as well be expensive paperweights.

Understanding the complex network of ductwork that operates within the walls and ceilings of your home is crucial for ensuring the optimal performance of your HVAC system. This intricate system, designed to distribute conditioned air throughout your living spaces, plays a pivotal role in maintaining indoor comfort and air quality.

Beyond its fundamental task of air distribution, well-designed and maintained ductwork contributes significantly to the energy efficiency of your heating and cooling systems, potentially saving you on utility costs.

What to Expect from This Guide

This guide aims to provide a comprehensive overview of ductwork systems, emphasizing their importance in residential and commercial buildings. Here’s a detailed breakdown of what we will cover:

Purpose: Gain an understanding of how ductwork is the silent hero of your HVAC system, ensuring that heated or cooled air is efficiently distributed throughout your home.

Types of Ductwork and Their Applications: Explore the variety of ductwork available, including traditional sheet metal, flexible ducts, and fiberglass options. Learn about the advantages and ideal applications of each type to understand what best suits different environments and needs.

Key Components and Their Functions: Delve into the essential parts that make up a ductwork system, such as ducts, fittings, dampers, and insulation materials. This section will highlight how each component contributes to the overall efficiency and effectiveness of your HVAC system.

Ductwork Design: The fundamentals of ductwork design, focusing on optimizing HVAC efficiency and comfort. This section covers essential design principles, sizing, and material selection to enhance airflow and indoor climate control.

Understanding Airflow Dynamics: Uncover the principles of airflow within duct systems, including how air moves, the importance of proper sizing and design, and how these factors influence your system's energy efficiency and the comfort levels in your home.

Maintenance and Professional Care: While not focused on DIY, it's important to recognize the value of regular maintenance and professional inspections. This segment will outline the key maintenance tasks that should be performed by qualified professionals to ensure your ductwork remains in optimal condition.

Energy Efficiency and Sealing Techniques: Learn about the significance of sealing and insulating ductwork to prevent energy loss. This section will discuss how professional sealing techniques and proper insulation can enhance system performance and reduce energy costs.

Safety and Air Quality Considerations: Address the critical aspects of fire safety and indoor air quality related to ductwork. We'll explore the incorporation of fire dampers, smoke detectors, and the role of ductwork in maintaining clean, healthy air within your home.

Emerging Technologies and Future Trends: Look ahead at the innovations shaping the future of ductwork, from smart HVAC integration to sustainable materials and designs. This will include a discussion on how these advancements can lead to greater efficiency, improved air quality, and enhanced user control.

By reading through this guide, you will gain valuable insights into how ductwork systems function and why they are a critical component of your HVAC system. Whether you’re interested in enhancing your home’s energy efficiency, improving indoor air quality, or simply seeking to understand how your HVAC system achieves its comfort goals, this guide will provide you with a thorough understanding of the essential role ductwork plays in these processes.

HVAC Ductwork Types: A Comprehensive List

Ductwork comes in many shapes and sizes, each with its own set of pros and cons. For instance, you've got your flexible ductwork, a favorite for tight spaces but not without its airflow resistance issues. Then there's the sturdy metal ductwork, lasting ages but requiring a bit more effort to install. And don't forget the fiberglass ductwork, offering superb insulation but raising concerns about air quality. Choosing the right type depends on your specific needs, budget, and installation environment.

When outfitting your HVAC system, the ductwork you choose is as crucial as the system itself. It's not just about moving air; it's about ensuring efficiency, longevity, and the comfort of your space. Beyond the basic categories of flexible, metal, and fiberglass ductwork, there are nuanced options within each type. Understanding these can help you make informed decisions tailored to your specific needs. Here’s a deeper dive into the world of HVAC ductwork.

Flexible Ductwork

Spiral Duct: This type is crafted from a metal wire coil wrapped in durable plastic, striking a balance between strength and flexibility. Its design is particularly useful for navigating tight spaces and complex layouts, making it a go-to for retrofit installations where traditional rigid ducts won’t fit.

Snaplock Duct: Known for its lightweight nature and ease of installation, snaplock duct is often employed for applications like dryer vents or other low-pressure scenarios. Its simplicity is a boon for DIY projects, allowing for quick setup without compromising on reliability.

Fiberboard Duct: Constructed from compressed fiberglass and a resin binder, fiberboard ductwork is notable for its inherent insulation properties. However, it's worth noting that this type can be a concern for dust accumulation and mold growth, requiring careful consideration in humid or unconditioned spaces.

Metal Ductwork (Rigid Ductwork)

Galvanized Steel: This is a stalwart in the ductwork realm, prized for its durability and cost-effectiveness. While it's a common choice across both residential and commercial installations, its susceptibility to rust necessitates proper coating or maintenance, especially in damp environments.

Aluminum: Aluminum ductwork stands out for its light weight and resistance to corrosion, making it suitable for a variety of settings, including exposed installations where aesthetics are a consideration. Its malleability, however, means it can be prone to dents and damage if not handled with care.

Stainless Steel: At the pinnacle of durability and corrosion resistance is stainless steel ductwork. It's the premium choice for environments that demand the utmost in cleanliness and moisture resistance, such as high-humidity areas or cleanrooms. The trade-off for its unparalleled quality is, naturally, a higher cost.

Fiberglass Duct Board: Excelling in insulation and noise reduction, fiberglass duct board offers a quieter and more energy-efficient option. However, the potential health risks associated with fiberglass necessitate professional handling and installation to mitigate exposure to airborne particles.

Semi-Rigid Ductwork

Oval Duct: This ductwork variant provides an optimal airflow pathway, surpassing round ducts in efficiency while saving space. It’s an excellent choice for areas where space is at a premium or in exposed settings where aesthetics matter.

Rectangular Duct: The most versatile and commonly used in commercial settings, rectangular ductwork facilitates efficient air distribution in a variety of configurations. Its adaptability makes it a staple in the HVAC industry, capable of fitting into nearly any building design.

Other Specialized Ductwork

Insulated Metal Ductwork: By integrating metal's structural strength with added insulation, this ductwork type enhances the energy efficiency of HVAC systems, reducing heat loss in winter and heat gain in summer.

Acoustic Ductwork: Designed with sound-absorbing materials, acoustic ductwork minimizes noise transmission from the HVAC system, ensuring a quieter environment. It's ideal for settings where noise reduction is a priority, such as recording studios or quiet office spaces.

Fire-Rated Ductwork: Engineered to withstand high temperatures and prevent the spread of fire, fire-rated ductwork is a critical component in building designs that prioritize safety. Its construction meets stringent building codes, offering peace of mind in commercial and residential applications.

Additional Considerations

- Size and Shape: The dimensions of ductwork should align with your system's airflow requirements and the physical constraints of your space. Incorrect sizing can lead to inefficiency and discomfort.

- R-value (Insulation): The insulation level of your ductwork, indicated by its R-value, should be chosen based on your climate and the need to minimize energy loss.

- Airtightness: Proper sealing of ductwork is essential to prevent leaks, ensuring that air is delivered efficiently throughout your space. Techniques like mastic sealing or specialized tape can improve airtightness.

- Cost: While budget considerations are inevitable, it's important to balance initial costs against the long-term benefits of durability, energy efficiency, and maintenance needs.

Selecting the right ductwork for your HVAC system involves weighing various factors, from material properties and installation challenges to budget constraints and energy efficiency goals.

Consulting with an HVAC professional can provide you with advice and insights, helping you navigate the selection process to find the best fit for your system and space. Whether upgrading an existing setup or installing a new system, the right ductwork is key to achieving optimal performance and comfort.

Key Components: Structural Components

To get into the intricacies of HVAC ductwork requires an appreciation for its structural and functional components. This complex system, integral to maintaining a comfortable indoor environment, consists of various elements each playing a pivotal role. Let's explore these components in detail, shedding light on their importance and how they contribute to the overall efficiency and safety of your HVAC system.

Ducts

At the heart of any HVAC system lie the ducts. These are the conduits through which conditioned air is transported throughout your home. Ducts are not one-size-fits-all; they vary significantly in shape, size, and material to accommodate different spaces and efficiency requirements.

For example, metal ducts, known for their durability and resistance to mold, are a common choice for long-term use. Flexible ducts, on the other hand, are easier to install in tight or awkward spaces but may not offer the same longevity or airflow efficiency. Fiberglass ducts offer excellent insulation properties, reducing heat loss or gain as air travels through your home, yet they require careful handling to maintain air quality.

Hangers and Supports

Keeping these ducts in place are hangers and supports, designed to prevent sagging or vibrating which can compromise system efficiency and longevity. These supports come in various forms, such as U-bolt hangers for secure mounting, trapeze hangers for suspending ducts from ceilings, strut hangers for versatile support configurations, and spring hangers that can absorb vibrations, minimizing noise and wear on the ductwork.

Sealing Materials

Ensuring the airtightness of duct connections are sealing materials like mastics and tapes. An unsealed or poorly sealed duct system can leak up to 30% of its air, leading to significant energy waste and reduced system efficiency. Properly applied sealants and tapes create impermeable barriers at joints and seams, keeping conditioned air where it belongs.

Connective Components

Fittings

Fittings play a crucial role in ductwork, allowing for seamless transitions between duct sections, changes in direction, and connections to outlets and inlets. These include elbows (for directional changes), tees (for branching), reducers and increasers (to change duct size), and transitions (to shift from one duct shape to another), ensuring the ductwork layout conforms to the architectural constraints of the building while maintaining efficient airflow.

Couplings

For straight sections of ductwork, couplings provide a secure and leak-proof connection. They can be either rigid or flexible, with the choice depending on the specific application and the need for accommodating movement or vibration without compromising the integrity of the duct system.

Collars

Collars serve as the interface between the ducts and the air distribution outlets, such as registers, grilles, and diffusers. These components ensure that airflow is distributed properly throughout the building, contributing to uniform temperature and air quality in every room.

Airflow Control Components

Dampers

Dampers are key to regulating airflow, allowing for the adjustment of temperature and pressure across different zones within a home. Manual dampers offer simple, cost-effective control, whereas automatic dampers can be integrated into smart HVAC systems for more precise, programmable airflow management.

Volume Control Dampers (VCDs)

VCDs adjust the volume of air flowing through a duct, playing a critical role in the initial balancing of the HVAC system. By modulating airflow, these dampers help achieve the desired environmental conditions in each area of the home.

Balancing Dampers

Similar to VCDs, balancing dampers fine-tune the airflow to specific zones or rooms, ensuring that each space receives adequate ventilation and heating or cooling. This is crucial for maintaining consistent comfort levels throughout the home.

Backdraft Dampers

Backdraft dampers prevent reverse airflow within the duct system, reducing energy waste and preventing the infiltration of unwanted dust, debris, or odors. These dampers are particularly important in exhaust ducts, where maintaining directional airflow is essential for system efficiency and indoor air quality.

Safety Components

Fire Dampers

In the event of a fire, fire dampers automatically close to prevent the spread of flames and smoke through the duct system. These components are a critical aspect of building safety, ensuring that fire containment measures are effective and that occupants have the time needed to evacuate safely.

Smoke Detectors

Smoke detectors within the duct system provide early warning of fire, triggering alarms and activating safety measures like the closing of fire dampers. These devices are essential for the early detection of smoke, allowing for a swift response to potential fire incidents.

Additional Components

Cleanouts

Cleanouts offer access points for the cleaning and maintenance of ducts, ensuring that airflow remains unobstructed by dust, debris, or other contaminants. Regular cleaning is essential for maintaining air quality and system efficiency.

Insulation

Insulation applied to ducts minimizes heat loss or gain as air travels through the system, significantly improving energy efficiency. Proper insulation can lead to substantial savings on heating and cooling costs while ensuring that living spaces reach and maintain desired temperatures more effectively.

Access Panels

Access panels provide entry to otherwise hidden sections of ductwork, facilitating inspection, maintenance, and repair. These panels are vital for addressing issues within the duct system without needing to remove large sections of wall or ceiling materials.

Knowing the function and importance of each component within the ductwork system, homeowners and HVAC professionals can ensure that HVAC systems operate efficiently, safely, and effectively.

Proper ac installation, maintenance, and periodic upgrades of these components contribute to the longevity of the system, optimal comfort levels, and energy savings. This comprehensive approach to HVAC ductwork underscores the complexity and significance of a well-designed and well-maintained duct system in achieving a comfortable and safe indoor environment.

Ductless Air Conditioning Systems

In the world of heating, ventilation, and air conditioning (HVAC), ductless air conditioners, also known as mini-split systems, have emerged as a highly efficient alternative to traditional systems that rely on extensive ductwork. These systems offer a versatile and energy-efficient solution for cooling (and heating) individual rooms or zones within a home or commercial space. Understanding the mechanics, benefits, and considerations of ductless air conditioning can help homeowners and businesses make informed decisions about their HVAC needs.

What is a Ductless Air Conditioner?

A ductless air conditioner consists of two main components: an outdoor compressor/condenser unit and one or more indoor air-handling units. These components are connected by a conduit that houses the power cable, refrigerant tubing, suction tubing, and a condensate drain. The absence of ducts in these systems eliminates the energy losses associated with the ductwork of central forced air systems, making them more energy-efficient.

Benefits of Ductless Air Conditioning Systems

- Energy Efficiency: Ductless systems have higher energy efficiency ratings compared to traditional ducted systems. They target specific areas, reducing energy waste and lowering utility bills.

- Flexible Installation Options: The compact size and flexibility of indoor air-handling units allow for a variety of installation options. They can be mounted on walls, suspended from ceilings, or even installed as floor-standing units.

- Improved Indoor Air Quality: Without ductwork, there's no risk of pollutants or allergens being circulated throughout your home. Many ductless units come equipped with multi-stage filtration to further reduce dust, bacteria, pollen, and other particulates in the air.

- Zoned Cooling and Heating: Ductless systems can be designed to cool or heat individual rooms or zones, providing personalized comfort settings for each area and reducing energy consumption by not conditioning unused spaces.

Considerations When Choosing a Ductless System

- Initial Cost: The upfront cost of a ductless air conditioning system can be higher than that of traditional systems, especially when multiple indoor units are required. However, the potential energy savings over time can offset the initial investment.

- Aesthetic Impact: Indoor units are visible within the living space, which may not suit every homeowner's aesthetic preferences. However, modern units are designed to be sleek and unobtrusive.

- Professional Installation: To ensure efficiency and reliability, ductless systems should be installed by qualified HVAC professionals. Proper sizing and placement of the indoor units are crucial for optimal performance.

Applications for Ductless Air Conditioning

Ductless systems are ideal for:

- Homes without existing ductwork, such as older homes or additions/extensions.

- Spaces requiring individual temperature control, like offices, bedrooms, or apartments.

- Situations where extending or installing ductwork is impractical or too expensive.

The Future of Ductless Air Conditioning

As technology advances, ductless air conditioning systems continue to evolve, becoming smarter, more efficient, and more integrated with home automation systems. Features like Wi-Fi connectivity, smart thermostats, and energy usage tracking are becoming standard, offering users unprecedented control over their indoor environments.

Ductless air conditioners represent a significant shift towards more energy-efficient, customizable, and environmentally friendly cooling and heating solutions. Whether for residential or commercial applications, they offer a compelling alternative to traditional ducted systems, aligning with modern demands for comfort, efficiency, and sustainability.

Designing Ductwork Systems

Planning your ductwork layout, whether it's for a new install or updating an existing system, involves understanding airflow, duct sizing, and material selection, not to mention compliance with building codes. Whether you're considering traditional metal ductwork or flexible options, good design ensures efficient, balanced heating and cooling throughout your home.

An effective ductwork design not only ensures comfort and air quality but also contributes to the energy efficiency of the HVAC system, reducing operational costs over the building's lifespan. This comprehensive section will delve into the intricacies of ductwork design, covering everything from the initial planning stages to the selection of materials, the use of design tools, and the importance of adhering to industry standards and building codes.

Residential Duct System Design for 1 Story Home

Residential Duct System Design for 2 Story Home

Residential Duct System Design for 3 Story Home

Initial Planning and Assessment

The first step in ductwork design involves a thorough assessment of the building's layout, the HVAC system's requirements, and the specific needs of the occupants. This phase includes calculating the heating and cooling loads, which will influence the size and configuration of the ductwork. Factors such as the building's insulation, window placements, and the local climate play critical roles in these calculations. The goal is to create a balanced system that delivers air efficiently to all parts of the building without overburdening the HVAC equipment.

Understanding Airflow Dynamics

A key aspect of ductwork design is mastering airflow dynamics. Airflow within a duct system is influenced by duct size, shape, and layout, as well as the speed at which air is pushed through the system. Properly designed ductwork minimizes resistance and turbulence, which can reduce system efficiency and increase noise levels. Designers must also consider the placement of supply and return vents to ensure optimal air circulation and prevent pressure imbalances.

Duct Sizing and Material Selection

Choosing the right size for ducts is crucial for system performance. Ducts that are too small can restrict airflow, leading to inefficiencies and uncomfortable temperature variations.

Oversized ducts can increase the cost of the system and take up unnecessary space. Material selection is equally important, with options ranging from traditional sheet metal to flexible ducts and fiberglass duct boards, each offering distinct advantages and challenges.

Compliance with Building Codes and Standards

Adherence to building codes and HVAC design standards is non-negotiable in ductwork design. These regulations ensure that duct systems are safe, efficient, and effective.

The International Code Council (ICC) and the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) provide comprehensive guidelines that cover everything from minimum efficiency standards to fire safety requirements. Designers must stay updated on these standards to ensure compliance and optimal system performance.

Designing ductwork systems is a multifaceted process that requires careful planning, a deep understanding of airflow dynamics, and strict adherence to codes and standards. By leveraging the right tools and working with experienced professionals, it's possible to create ductwork systems that enhance the comfort, air quality, and energy efficiency of any space. As technology and materials continue to evolve, staying informed and adaptable will be key to achieving success in the field of ductwork design.

Online Tools for Designing Ductwork Systems

A variety of online tools and software can aid in the design and planning of ductwork systems. From basic calculators like the National Comfort Institute's Ductulator to advanced BIM software such as Autodesk Revit, these resources offer valuable assistance in visualizing duct layouts, calculating material requirements, and optimizing airflow.

Computational Fluid Dynamics (CFD) software, like ANSYS Fluent and SimScale, allows for detailed simulation of airflow within duct systems, enabling designers to identify and address potential issues before installation.

Sometimes, engineers use special computer programs to figure out the best way to design the ducts in your house, just like using a video game to simulate building something before you build it in real life. This helps them make sure the air flows just right, making your house as comfortable as it can be without wasting energy.

General Design and Planning

- National Comfort Institute (NCI) Ductulator: https://nationalcomfortinstitute.com/pro/index.cfm?pid=1779

- Calculates duct sizes based on airflow and pressure needs.

- Free tool with basic features.

- Sheet Metal Estimator https://www.xometry.com/resources/sheet/sheet-metal-fabrication-cost-calculator/

- Estimates material costs for ductwork based on user-defined parameters.

- Free tool with limited customization options.

- CADpro: https://www.cadpro.com/product/cad-pro-platinum-edition/

- 2D/3D design software for sheet metal fabrication, including ductwork.

- Paid software with a free trial version available.

- SketchUp: https://www.sketchup.com/

- 3D modeling software with capabilities to design basic layouts and visualize ductwork placement.

- Free version with limited features, paid versions offer more functionality.

Advanced Design and Analysis

- Autodesk Revit: https://www.autodesk.com/products/revit/overview

- BIM (Building Information Modeling) software for comprehensive building design, including HVAC systems with detailed ductwork layouts.

- Paid software with a steep learning curve.

- ANSYS Fluent: https://www.ansys.com/products/fluids/ansys-fluent

- Computational Fluid Dynamics (CFD) software for advanced airflow simulation and optimization of ductwork designs.

- Paid software requiring engineering expertise.

- SimScale: https://www.simscale.com/

- Cloud-based CFD platform offering access to advanced simulation tools for ductwork analysis.

- Free plan with limited features, paid plans for more complex simulations.

Online Resources and Communities

- International Code Council (ICC): https://www.iccsafe.org/

- Provides access to building codes and standards relevant to ductwork design.

- Free access to basic information, paid subscriptions for full code access.

- ASHRAE Standards: https://www.ashrae.org/technical-resources/standards-and-guidelines

- Offers HVAC design standards and guidelines, including those related to ductwork.

- Free access to limited information, paid subscriptions for full standards access.

While online tools can assist with planning and estimation, consulting a qualified HVAC professional is crucial for complex designs, ensuring code compliance, and guaranteeing optimal system performance. They can tailor the approach to your specific needs and provide expert guidance throughout the process.

Understanding Airflow Dynamics

Understanding airflow dynamics within HVAC ductwork systems is pivotal for ensuring the efficiency and effectiveness of air distribution throughout a building. This intricate process is governed by fundamental principles of physics and fluid dynamics, significantly impacting the system's overall energy efficiency and the comfort levels within the indoor environment.

To delve into this topic, we must explore the principles of air movement, the influence of ductwork design on airflow, and strategies for optimizing airflow to enhance system performance.

Principles of Air Movement in Duct Systems

Airflow in duct systems is driven by differences in air pressure. The HVAC system's blower or fan creates a high-pressure area at the air handler's output, propelling air into the ductwork. From there, air moves towards areas of lower pressure, which are typically the conditioned spaces in a building. The rate at which air moves through the ducts and the pressure differences that drive this movement are crucial for achieving efficient air distribution.

Imagine you have a balloon filled with air. If you release the end, air rushes out from the high-pressure inside the balloon to the lower-pressure outside. Your HVAC system works a bit like the balloon, but instead of letting air out randomly, it pushes air through pipes (ducts) to warm up or cool down your house. The fan in your HVAC system is like your hands squeezing the balloon to let air out.

The Role of Ductwork Design in Airflow Dynamics

The design of ductwork significantly influences airflow dynamics. Optimal design ensures that air moves smoothly through the ducts, reaching all parts of the building effectively. Several factors within ductwork design play pivotal roles in this context:

- Duct Size: Correct sizing of ducts is essential. Undersized ducts restrict airflow, causing the system to work harder, leading to inefficiencies and increased wear on system components. Oversized ducts, while less common, can result in insufficient air velocity, impairing effective air distribution and temperature control.

- Duct Shape and Layout: The shape of ducts (round, rectangular, or oval) and their layout within the building affect airflow resistance. Round ducts typically offer the least resistance, while sharp bends, long horizontal runs, and unnecessary turns in the duct layout can increase resistance and reduce airflow efficiency.

- Type and Number of Fittings: Fittings such as elbows, tees, and transitions introduce additional resistance to airflow. The design challenge is to minimize the use of these fittings or choose designs that offer the least airflow disruption.

- Material: Duct material can also affect airflow dynamics. Smooth interior surfaces, as found in metal ductwork, minimize air resistance. In contrast, flexible ducts, if not properly installed, can sag or bend, increasing resistance.

Think about trying to drink a thick milkshake. If you use a thin straw, it's hard to suck the milkshake up, and you have to work really hard to get a sip. But if you use a wide straw, it's much easier. Ducts in your house are like those straws. If they're too small (thin straw), the air (milkshake) can't move through them easily, and the system has to work harder. But they can't be too big either, or the air won't move fast enough to get to where it needs to go. The shape of the ducts and how straight or bendy their path is also affects how easily air can move, just like a straight straw versus one with lots of twists and turns.

Optimizing Airflow for Efficiency and Comfort

Enhancing airflow dynamics involves not only addressing the physical aspects of the ductwork but also ensuring that the system is balanced and that air distribution is effectively managed:

- System Balancing: Balancing involves adjusting the airflow to different parts of the building to ensure even distribution. This may require manual or automatic dampers that can regulate airflow in specific duct segments.

- Leak Sealing: Duct leaks can significantly impact airflow dynamics by allowing conditioned air to escape before reaching its intended destination. Sealing leaks with mastic or foil tape is critical for maintaining system pressure and efficiency.

- Insulation: Proper insulation of ductwork, especially in unconditioned spaces, helps maintain air temperature as it moves through the system, reducing energy loss and improving comfort.

- Regular Maintenance: Routine inspection and maintenance of ductwork, including cleaning and repairs, ensure that airflow dynamics are not compromised over time.

Just like you might adjust how you're holding the straw to drink the milkshake more easily, sometimes the airflow in your house needs a little adjustment. This can mean making sure the air is shared equally in all rooms or fixing any places where air might be leaking out of the ducts before it gets to where it's supposed to go. Keeping the ducts clean and making sure they're wrapped up snugly (insulated) so they don't lose any warmth or coolness as the air travels through them is also important.

Advanced Considerations in Airflow Dynamics

Advanced technologies and design approaches can further optimize airflow dynamics. Computational Fluid Dynamics (CFD) software allows for detailed analysis and simulation of airflow within duct systems, enabling designers to identify and mitigate potential issues before installation. Additionally, innovative duct designs and materials are continuously being developed to reduce resistance and improve air distribution efficiency.

Fluid Dynamics and Pressure Differences

The principles of fluid dynamics play a crucial role in the movement of air through HVAC duct systems. At its core, fluid dynamics is the study of fluids (liquids and gasses) in motion. Air, being a gas, adheres to these principles, which dictate that air moves from areas of higher pressure to areas of lower pressure. This fundamental concept is what drives the airflow within ductwork, facilitated by the HVAC system's blower.

When the HVAC system operates, the blower creates a high-pressure zone at its output. This pressure differential propels the air into the ductwork, initiating the movement towards the lower-pressure areas, which are the spaces within a building requiring heating, cooling, or ventilation. The efficiency with which this air moves depends largely on the design of the ductwork system.

Duct size, shape, length, and the presence of fittings such as elbows, tees, and transitions can either facilitate this movement or present resistance, which can impede airflow. For instance, smoother duct interiors and fewer sharp turns reduce turbulence and resistance, allowing air to flow more freely. This optimization of airflow is not just about achieving comfort but also about ensuring that the HVAC system operates as efficiently as possible, conserving energy and extending the life of the system.

Strategic Placement of Vents

The strategic placement of supply and return vents is another pivotal aspect of ductwork design that significantly influences system efficiency and occupant comfort. Proper placement ensures balanced air circulation, effectively distributing conditioned air throughout the building while also facilitating the return of air back to the HVAC system for reconditioning.

Supply vents should be positioned to evenly disperse air in occupied spaces, avoiding areas where furniture or other obstacles can block airflow. Return vents are equally important; they must be placed in locations that allow for the unimpeded movement of air back to the HVAC system.

This careful positioning helps maintain a balanced pressure within the duct system, preventing scenarios where some areas might become pressurized (positive pressure) and others might experience a vacuum (negative pressure). Such imbalances can lead to comfort issues, with some rooms being too hot or too cold, and can force the HVAC system to work harder, reducing its efficiency and lifespan.

Eco-friendly Materials and Practices

Incorporating eco-friendly materials and sustainable practices into the design and construction of ductwork systems represents a forward-thinking approach to HVAC design.

Using recycled materials for duct fabrication not only reduces the environmental impact associated with new material production but also promotes sustainability within the industry. Materials such as recycled steel or aluminum for metal ducts, and post-consumer recycled plastic for flexible ductwork, are examples of how eco-friendly practices can be integrated into ductwork design.

Moreover, the application of advanced technologies plays a significant role in reducing energy use and minimizing the environmental footprint of HVAC systems. For instance, ductwork can be designed and installed to maximize energy efficiency through the use of automated control systems that adjust airflow based on real-time demand or through the installation of highly efficient insulation materials that minimize thermal loss.

By prioritizing eco-friendly materials and practices, HVAC professionals can contribute to the creation of systems that not only provide optimal comfort and efficiency but also align with broader environmental sustainability goals. These efforts help reduce the overall energy consumption of buildings, contribute to a reduction in greenhouse gas emissions, and promote a healthier environment for future generations.

Airflow dynamics is crucial for designing, installing, and maintaining efficient HVAC ductwork systems. By considering the factors that influence air movement and employing strategies to optimize airflow, it is possible to enhance system performance, reduce energy consumption, and ensure comfortable indoor environments.

Understanding how air moves around your house and making sure it does so efficiently is a bit like ensuring you can enjoy your milkshake with the perfect straw. You want the straw to be just the right size and shape, and you don't want any holes in it leaking your milkshake. By paying attention to how the ducts in your house are designed and taken care of, you can keep your home feeling just right without making your HVAC system work too hard.

Maintaining and Improving Your Ductwork

Now, even the best systems run into trouble – condensation on ductwork, mold, and leaks can bring down the party. Recognizing these issues early on can save you a ton of hassle and money. For instance, spotting condensation early can prevent a mold fest, and finding leaks can stop your energy bills from skyrocketing. It's about keeping an eye out and acting fast.

Now, even the best systems run into trouble – condensation on ductwork, mold, and leaks can bring down the party. Recognizing these issues early on can save you a ton of hassle and money. For instance, spotting condensation early can prevent a mold fest, and finding leaks can stop your energy bills from skyrocketing. It's about keeping an eye out and acting fast.

Maintenance

Regular maintenance, including cleaning ductwork, is essential to prevent common problems like mold and leaks. It's not just about air quality; it's about system efficiency. Regular check-ups can identify small issues before they become big problems, saving you money and ensuring your home stays comfortable year-round.

DIY Ductwork Cleaning

When it comes to cleaning ductwork, it's not just about dusting off the cobwebs. You'll need the right tools and techniques to get the job done without causing any damage. From using a high-powered vacuum to special brushes, cleaning ductwork can improve your system's efficiency and your home's air quality. Remember, if you stumble upon mold or a massive buildup, calling in the professionals might be the safer bet.

Upgrading Your Ductwork System

Sometimes, an upgrade is in order. Replacing ductwork or adding components like a ductwork booster fan can enhance system performance. If your system is old or was not properly installed, installing new ductwork can improve airflow and efficiency, leading to better temperature control and reduced energy usage.

Ductwork Installation and Repair

Professional Installation and Repair

Sometimes, the best approach is to call in the experts, especially for complex projects or repairs. When hiring professionals for ductwork installation or repair, do your homework. Look for reputable ductwork companies near me with good reviews and fair prices. They can handle everything from custom ductwork to repairing leaks and replacing old sections, ensuring your system operates at its best.

Advanced Ductwork Solutions

Innovative Materials and Techniques

The HVAC industry is constantly evolving, with new materials and techniques for ductwork offering better performance and easier installation. For example, custom ductwork made from advanced materials can provide superior insulation and durability, while low-profile ductwork is perfect for spaces where traditional ducts won't fit.

Smart Ductwork Systems

Integrating ductwork with smart home technology is another way to improve efficiency and control. Smart thermostats can adjust airflow to different areas of your home, optimizing temperature control and energy use. Smart home integration with your HVAC system not only makes your life easier but also helps in reducing your carbon footprint.

Professional Consultation and Installation

While many ductwork improvements can be DIY projects, some situations call for professional expertise. Whether it's designing a new system, installing ductwork, or making complex repairs, professionals can ensure that your system is efficient, safe, and up to code. Investing in professional ductwork services can save money in the long run by ensuring the job is done right the first time.

Attic Ductwork Considerations

Working with attic ductwork presents unique challenges. The attic is often subject to extreme temperatures, which can affect the efficiency of your HVAC system. When planning your attic ductwork layout, prioritize insulation to protect against heat loss in winter and heat gain in summer. This can significantly impact your home's overall energy efficiency and comfort.

Calculating CFM for Ductwork

Comprehension of CFM (Cubic Feet per Minute) is necessary when sizing ductwork. It’s all about matching the airflow needs of your space with the capabilities of your HVAC system. Utilizing a CFM chart for ductwork helps ensure that each room receives adequate airflow, enhancing comfort and system efficiency. Proper calculations can prevent issues like uneven heating or cooling and excessive wear on your HVAC system.

Choosing Ductwork Supplies and Tools

Selecting the right ductwork supplies and tools can make or break your installation or repair project. From mastic for sealing joints to a duct crimp tool for fitting pieces together, quality matters. Don’t forget about the importance of specialized ductwork tools for cutting and shaping materials, ensuring a professional-grade job even if you’re going the DIY route.

Opting for Low Profile or Oval Ductwork

In spaces where height is limited, low profile ductwork or oval ductwork can be a game-changer. These options provide the necessary airflow in tight spaces without sacrificing system efficiency. Ideal for basements or attics where traditional round or rectangular ducts won’t fit, these alternatives offer a versatile solution to common installation challenges.

When to Consider Ductwork Replacement

Sometimes, repairing old or inefficient ductwork is more trouble than it’s worth. If your system is plagued by leaks, inadequate insulation, or poor layout, replacing ductwork might be the best option. A ductwork replacement cost calculator can help you weigh the investment against the potential energy savings and improved comfort in your home.

Sealing and Insulation

Now, let's talk about keeping that air where it should be with sealing ductwork and insulation. These steps are crucial for minimizing energy loss. A well-sealed system prevents leaks, while proper insulation keeps the air at the right temperature as it travels through your home. You can use mastic or foil tape for sealing, and don't skimp on quality insulation material. It's a DIY project that pays off in comfort and savings.

Insulation and Sealing: A Closer Look

Properly insulating ductwork and sealing leaks are among the most cost-effective ways to enhance your HVAC system’s efficiency. Insulation keeps the air within the ducts at the desired temperature, reducing energy waste. Meanwhile, sealing ductwork with mastic or specialized tape prevents air leaks, ensuring that every bit of conditioned air reaches its intended destination.

A variety of sealants are available to tackle different types of leaks, from minor gaps to larger cracks, each with its own set of properties tailored to specific conditions and materials. Understanding the extensive list of sealants used in HVAC systems can help professionals and DIY enthusiasts alike choose the right product for their needs.

Mastic Sealants

Acrylic Mastic: This water-based sealant is prized for its flexibility and ease of application, making it a go-to choice for sealing a wide range of ductwork materials, including metal, fiberglass, and even concrete surfaces. Despite its versatility, acrylic mastic is not recommended for high-temperature environments or areas exposed to direct sunlight, limiting its use in certain HVAC applications.

Silicone Mastic: Known for its exceptional flexibility and heat resistance, silicone mastic outperforms acrylic variants in environments subject to extreme temperatures. It's particularly useful for sealing areas around furnaces and plenums. The primary drawbacks are its higher cost and the need for a primer when applied to specific surfaces.

Solvent-based Mastic: Distinguished by its incorporation of solvents, this type of mastic offers enhanced durability and resistance to moisture, making it suitable for outdoor use or in humid conditions. The trade-off comes in the form of a potent odor and the necessity for ample ventilation during its application.

Tape Sealants

Aluminum Foil Tape: Affordable and widely used, aluminum foil tape is effective for sealing small gaps and seams. Its reflective surface contributes to the insulation of ductwork. However, its susceptibility to tearing and poor adhesion to rough surfaces can limit its effectiveness.

Metalized Polyester Tape: Offering greater durability and resistance to tearing than its aluminum foil counterpart, metalized polyester tape is better suited for sealing larger gaps and irregular surfaces. It also provides improved heat resistance and acts as a more effective moisture barrier.

Self-Adhesive Mastic Tape: This tape combines the robust sealing capabilities of mastic with the ease of tape application. While convenient and effective at forming airtight seals, it may not be as widely available as other sealing options.

Other Sealants

Liquid Rubber Sealant: Ideal for sealing large gaps and cracks, liquid rubber provides a flexible, waterproof coating that can withstand extreme temperature fluctuations. While highly effective, its application can be messy, and it requires a significant curing time.

Caulking Compounds: Although not specifically designed for HVAC applications, certain caulking compounds can be utilized to seal small gaps and penetrations in ductwork. Selecting a compound with the necessary flexibility and heat resistance is crucial for ensuring effective and durable seals.

Each type of sealant offers distinct advantages and limitations, making the choice of sealant dependent on the specific requirements of the repair or maintenance task at hand. Factors such as the material of the ductwork, the environmental conditions, and the size and nature of the gaps to be sealed all play a role in determining the most suitable sealant.

By carefully selecting the appropriate sealant, HVAC professionals and homeowners can ensure the integrity of ductwork, optimize system performance, and maintain comfortable indoor environments.

Safety and Air Quality Considerations

Safety and Air Quality Considerations

Ensuring fire safety and maintaining indoor air quality are paramount in the design, installation, and maintenance of HVAC ductwork systems. These aspects not only contribute to the health and safety of the occupants but also play a significant role in preserving the integrity of the building's infrastructure.

This extensive exploration delves into the critical considerations for fire safety and indoor air quality within ductwork systems, offering insights into best practices, regulatory guidelines, and the latest advancements in the field.

Fire Safety in Ductwork Systems

Fire Dampers

Incorporating fire dampers into ductwork systems is essential for halting the spread of fire and smoke within a building. Fire dampers close automatically in response to a rise in temperature, typically triggered by a fusible link that melts at a specific temperature or by the detection of smoke.

These devices come in various types, including automatic, fusible-link, and motor-operated dampers, each designed to meet specific safety requirements. Proper placement, adhering to guidelines such as those outlined by the National Fire Protection Association (NFPA), is crucial for ensuring the dampers function effectively in an emergency. Regular maintenance and testing are mandated to guarantee their reliability over time.

Smoke Detectors in Ductwork

Integrating smoke detectors within ductwork systems enhances early fire detection capabilities, allowing for prompt activation of fire suppression systems and evacuation protocols. These detectors vary in technology, including photoelectric and ionization types, each suitable for different applications.

Strategic placement within the ductwork, informed by an understanding of airflow patterns, is vital for maximizing their effectiveness. Additionally, these detectors should be integrated with the building's alarm systems to ensure a coordinated response to fire emergencies.

Ductwork Materials and Fire Safety

The choice of ductwork materials significantly impacts the system's fire safety. Metal ducts, known for their non-combustibility, are preferred in areas at high risk for fire. Fiberglass and certain types of flexible ductwork, while offering advantages in specific applications, require careful consideration due to their varying fire resistance ratings. Employing fire-resistant materials, especially in high-risk areas near heating equipment, is a fundamental safety measure.

Maintenance and Cleaning for Fire Safety

Regular removal of combustible materials, such as accumulated dust and debris, is critical for minimizing fire hazards within ductwork. Inspections can identify potential risks, such as damaged sections that may compromise the system's integrity. Professional cleaning, adhering to standards set by organizations like the EPA, ensures the removal of materials that could fuel a fire, contributing to a safer environment.

Enhancing Indoor Air Quality through Ductwork Management

Ductwork as a Pathway for Contaminants

Ductwork can inadvertently become a conduit for mold, dust, allergens, and other pollutants, adversely affecting indoor air quality. Mold growth, in particular, poses significant health risks and requires proactive measures to prevent its occurrence. Ensuring ductwork is properly sealed and maintained helps mitigate these issues, safeguarding the health of building occupants.

Duct Cleaning Practices

The EPA provides guidelines on when and how duct cleaning should be performed, emphasizing the role of qualified professionals in this process. While not always necessary, cleaning becomes beneficial in specific circumstances, such as visible mold growth or verifiable dust and debris accumulation. The selection of experienced technicians is crucial for avoiding potential negative impacts on air quality post-cleaning.

Air Filtration and Ductwork

Upgrading to high-efficiency air filters, including HEPA filters, can significantly reduce the ingress of contaminants into ducts. These filters capture a broader range of particles, improving indoor air quality. However, maintaining proper airflow is essential to prevent undue stress on the HVAC system, underscoring the importance of regular filter maintenance.

Ventilation Design Considerations

Effective ventilation is key to achieving optimal indoor air quality. Proper ductwork design ensures fresh air is adequately introduced to indoor spaces while removing stale air. Professional design and installation are paramount in creating a balanced system that evenly distributes air, preventing areas of stagnation that could affect occupant comfort and health.

Leveraging Resources for Best Practices

Organizations such as the NFPA, EPA, and ASHRAE offer valuable resources for professionals and homeowners alike, providing access to best practices, safety guidelines, and research on fire safety and indoor air quality. These resources are instrumental in staying informed on the latest standards and technologies in HVAC system design and maintenance.

Addressing fire safety and indoor air quality considerations in ductwork systems requires a multifaceted approach, incorporating appropriate materials, design principles, and maintenance practices. By adhering to established guidelines and leveraging advancements in technology, it is possible to create HVAC systems that not only provide comfort but also ensure the safety and well-being of building occupants.

Emerging Technologies and Future Trends Sustainable Practices

Exploring energy-efficient and environmentally friendly ductwork materials and practices is not just good for the planet; it's great for your wallet too. Innovations in ductwork technology are making systems more efficient and sustainable, reducing your home's carbon footprint.

The integration of smart home technology and innovations in ductwork is revolutionizing how we manage and experience our indoor environments. These advancements offer unprecedented levels of convenience, energy efficiency, and control, reshaping our interaction with HVAC systems.

Below, we explore the benefits of smart home integration in HVAC systems, delve into the latest technologies and innovations in ductwork, and address key considerations for homeowners and professionals.

Smart Home Integration:

Benefits

- Convenience: Modern smart home systems enable users to adjust temperature, humidity, and airflow settings with simple voice commands or through intuitive smartphone applications. This ease of control enhances living comfort and adapts to the occupants' lifestyle seamlessly.

- Energy Efficiency: Smart home technologies allow for sophisticated scheduling based on occupancy, time of day, and personal preferences. By optimizing airflow and environmental conditions in different zones of a home, these systems can significantly reduce energy consumption and costs.

- Remote Monitoring: With smart home integration, homeowners can monitor their HVAC system's performance in real-time. This capability allows for the early detection of potential issues, facilitating prompt troubleshooting and maintenance, often before a minor issue escalates into a major problem.

- Integration with Other Systems: Smart HVAC systems can be integrated with a wide range of other smart home devices, including thermostats, lighting, and security systems. This approach to home automation provides a unified, efficient, and highly customizable living environment.

Technologies

- Smart Thermostats: These devices connect to home Wi-Fi networks, allowing users to control and program their HVAC systems remotely. Advanced models learn from user behaviors to make energy-saving adjustments automatically.

- Zone Control Systems: These systems enable independent temperature and humidity management in different areas, catering to the specific needs of each zone within a home.

- Integration Platforms: Various smart home platforms and protocols facilitate the connection and centralized control of diverse smart devices, creating a cohesive and intelligent home ecosystem.

- Smart Dampers: Installed within the ductwork, smart dampers can adjust airflow to specific rooms or zones, enhancing comfort and reducing energy waste.

Considerations

- Compatibility with the home's existing HVAC system and ductwork is crucial for seamless integration.

- Initial installation costs and the need for professional assistance can vary, influencing the decision-making process.

- Cybersecurity measures are essential to safeguard smart HVAC systems against unauthorized access and ensure user privacy.

Innovations in Ductwork Technology:

Advancements

- Ducted Mini-Split Systems: These systems combine the energy efficiency of traditional mini-splits with the ability to control individual rooms or zones, making them ideal for tailored heating and cooling solutions.

- Smart Dampers: Enhanced with automatic adjustments, smart dampers optimize airflow based on real-time data such as temperature readings, occupancy sensors, and pre-set preferences, promoting efficient energy use and comfort.

- Self-Sealing Connections: Innovations in duct connections minimize air leaks, improving system efficiency, reducing noise, and ensuring better indoor air quality.

- Insulated Flexible Ductwork: The use of advanced insulation materials reduces thermal loss or gain as air travels through the ducts, contributing to overall energy efficiency.

- Prefabricated Ductwork: Pre-built duct sections simplify the installation process, reduce labor costs, and offer higher precision and quality control compared to traditional on-site fabrication.

- Sustainable Materials: The development of ductwork materials from recycled content or bio-based alternatives aligns with growing environmental sustainability goals, offering greener options for HVAC systems.

Overall Impact

The fusion of smart home integration and cutting-edge ductwork technologies not only elevates the comfort and convenience of living spaces but also paves the way for significant energy savings and environmental benefits.

The fusion of smart home integration and cutting-edge ductwork technologies not only elevates the comfort and convenience of living spaces but also paves the way for significant energy savings and environmental benefits.

Enhanced system monitoring and the potential for integration with renewable energy sources further underscore the transformative potential of these advancements. As technology evolves, these innovations are set to redefine our expectations for residential and commercial HVAC systems, promising a future where comfort, efficiency, and sustainability go hand in hand.

By now, you should have a solid grasp of not just the basics but also some of the more nuanced aspects of ductwork maintenance, improvement, and installation. Whether tackling DIY projects, planning new installations, or simply seeking to understand how to enhance your home’s HVAC efficiency, remember that knowledge is power. Your efforts will not only improve comfort and air quality but also contribute to a more energy-efficient and sustainable home.

Frequently Asked Questions (FAQs) about HVAC Ductwork:

What type of ductwork is best for my home?

The optimal ductwork for your home hinges on a variety of considerations including your budget, the architectural design and constraints of your space, and the specific climate in which you reside. Metal ductwork is renowned for its durability and effectiveness in a wide range of environments, making it a common choice for both new constructions and renovations.

Flexible ductwork, while easier to install, especially in tight spaces, may not be as durable but offers significant installation flexibility. Fiberglass ductwork provides excellent insulation properties, which can enhance energy efficiency, although it requires careful handling to avoid compromising indoor air quality. Consulting with a qualified HVAC professional is crucial to evaluate your specific situation and recommend the most suitable type of ductwork for your home.

What size ducts do I need?

Selecting the correct duct size is pivotal for the efficiency and effectiveness of your HVAC system. Too small, and the system will have to work harder, possibly leading to increased energy usage and premature wear; too large, and you may experience inefficient air movement and temperature inconsistencies.

The sizing depends on several factors, including the size of your home, the layout of the ductwork, the type of HVAC system you have, and its capacity. HVAC professionals use detailed calculations conforming to industry standards, like the Manual J calculation for heating and cooling loads and the Manual D for ductwork design, to determine the most appropriate duct size for your specific needs.

Can I install ductwork myself?

Installing ductwork involves a complex understanding of HVAC systems, airflow dynamics, and building codes. While some aspects of ductwork installation, particularly involving flexible ducts or minor modifications, may be within the reach of experienced DIY enthusiasts, the majority of ductwork installation projects are best left to professionals.

This ensures that the ductwork is correctly sized, properly sealed and insulated, and installed in compliance with local codes and regulations. Professional installation also guarantees the safety and efficiency of your HVAC system, reducing the likelihood of issues that can arise from improper installation.

How much does it cost to install new ductwork?

The cost of installing new ductwork varies widely based on several factors, including the size of your home, the type and quality of materials used, the complexity of the installation, and labor costs in your area.

On average, homeowners can expect to spend anywhere from a few thousand dollars for a basic installation in a small home to tens of thousands for more extensive installations in larger properties or those requiring custom ductwork solutions. To get a clear understanding of the potential costs, it's advisable to obtain multiple quotes from reputable HVAC contractors who can provide a detailed assessment and estimate based on your specific requirements.

Can I add ductwork to an existing system?

Adding ductwork to an existing HVAC system is possible but requires careful consideration of the system's capacity, the layout of the existing ductwork, and the structural constraints of your home. An HVAC professional can assess whether your current system can handle the additional load and determine the most efficient way to integrate new ductwork.

This may involve upgrading the HVAC unit, modifying the existing ductwork layout, or adding zoning controls to manage airflow effectively. Consulting with a professional ensures that any expansion of your ductwork is done in a way that maintains system efficiency, comfort, and compliance with building codes.

How often should I clean my ducts?

The frequency of duct cleaning can depend on several factors, including the presence of pets, household size, allergy concerns, and whether the home is located in a high-dust area or has a smoker. Generally, it's recommended to have your ducts professionally cleaned every 3 to 5 years. However, if you notice signs of significant dust buildup, mold growth, or if allergies and respiratory issues become more pronounced at home, it might be time to consult a professional cleaner sooner.

Can I clean my ducts myself?

While homeowners can perform basic duct maintenance, such as vacuuming accessible parts of the ducts and ensuring vents are not blocked, comprehensive duct cleaning typically requires specialized tools and knowledge. Professional duct cleaning services use high-powered vacuums, brushes, and other equipment to thoroughly clean the ductwork. DIY cleaning without the proper tools can potentially push contaminants further into the system or damage the ductwork, leading to more significant issues.

What are the benefits of cleaning my ducts?

Cleaning your HVAC ducts offers several benefits, including improved indoor air quality by reducing dust, mold spores, and other allergens circulating through your home. It can also enhance your HVAC system's efficiency by removing obstructions that restrict airflow, leading to lower energy bills and extending the life of your heating and cooling equipment. Additionally, it can help eliminate odors, creating a fresher living environment.

How much does duct cleaning cost?

The cost of duct cleaning can vary widely depending on the size of your duct system, the complexity of the job, and your geographical location. On average, homeowners might expect to pay between $300 and $700 for a full duct cleaning service, with larger homes or those with more complicated duct systems potentially costing more. It's wise to get quotes from several reputable service providers to ensure you're getting a fair price.

Are there any risks associated with duct cleaning?

If performed by a reputable, experienced professional, duct cleaning should pose minimal risk to your ductwork or home. However, choosing an inexperienced or poorly equipped service provider can lead to damaged ducts, reduced system efficiency, and disturbed asbestos-containing materials (if present in older homes). Always ensure the duct cleaning company is certified, well-reviewed, and experienced with systems like yours.

Why is my system blowing cold/hot air in some rooms?

Inconsistent temperatures in your home can be caused by various factors, including leaky ductwork, improper system sizing, blocked vents, or inadequate insulation. It's essential to have an HVAC professional conduct a thorough inspection to identify the root cause and recommend solutions to your ductwork as well as your HVAC system , which may include duct sealing or repair, system rebalancing, or adding zoning controls for better temperature management.

How can I improve the airflow in my ductwork?

Improving airflow can be achieved by ensuring that ducts are properly sealed and insulated, free from blockages, and correctly sized for your home. Regular maintenance, including filter changes and duct inspections, can prevent airflow issues. Additionally, installing dampers or upgrading to a ductwork system designed for better airflow can also enhance performance.

What is the R-value for ductwork insulation?

The R-value needed for ductwork insulation varies based on your climate zone and the location of the ducts (e.g., attic, basement, conditioned space). Generally, duct insulation R-values range from R-6 for mild climates to R-8 for colder areas, as recommended by the U.S. Department of Energy. An HVAC professional can recommend the appropriate insulation level for your ductwork to maximize energy efficiency and comfort.

How can I tell if my ducts are leaking?

Signs of leaking ducts include higher than expected energy bills, difficulty maintaining consistent temperatures, rooms that feel stuffy or have poor air flow, and visible dust accumulation near vents. You may also hear whistling sounds from the ductwork. A professional HVAC technician can conduct a pressurization test to definitively identify leaks and recommend the best sealing solutions.

What are the benefits of insulating my ducts?

Insulating your ducts helps maintain the temperature of the air as it travels from your HVAC system to the vents, reducing energy loss, improving system efficiency, and lowering heating and cooling costs. It can also prevent condensation on ducts in humid conditions, which can lead to mold growth and air quality issues. Properly insulated ducts contribute to a more comfortable and consistent indoor climate.

What are the different types of duct materials?

The primary materials used in ductwork include sheet metal (galvanized steel or aluminum), fiberglass duct board, and flexible ducting made from wire coils covered in plastic or fabric. Each material has its benefits and ideal applications.

Sheet metal is durable and less likely to harbor mold or pests, making it a popular choice for most HVAC systems. Fiberglass duct board offers excellent thermal and acoustic insulation, reducing energy loss and noise. Flexible ducts are easier to install, especially in tight spaces, but require careful handling to prevent damage and ensure longevity.

What are the pros and cons of flexible ductwork?

Pros: Flexible ductwork is versatile and easy to install, making it ideal for tight spaces and complex layouts. It can be more cost-effective than rigid ductwork and is relatively easy to connect to existing systems.

Cons: It can be more susceptible to damage, such as tears or kinks, which can compromise airflow and system efficiency. Flexible ducts may also be more prone to sagging over time, and if not properly supported, can lead to reduced air flow and increased energy costs.

What are the pros and cons of metal ductwork?

Pros: Metal ductwork, typically made from galvanized steel or aluminum, is highly durable and resistant to mold and pests. It can handle high air pressure and is less likely to develop leaks than other types of ductwork. Metal ducts are also fire-resistant and can be recycled, making them an environmentally friendly option.

Cons: Metal ductwork can be more expensive to install due to the materials' cost and the labor involved in cutting and fitting the ducts. It can also be noisier than other types of ductwork without proper insulation and can conduct heat, leading to energy loss if not adequately insulated.

What are the pros and cons of fiberglass ductwork?

Pros: Fiberglass duct board provides excellent insulation, helping to maintain air temperature and reduce energy loss. It also absorbs sound, which can reduce noise from the airflow and system operation.

Cons: Fiberglass particles can be a health concern if the ductwork is not properly sealed. It is also susceptible to moisture and mold growth, requiring careful installation and maintenance to ensure indoor air quality is not compromised.

What are duct dampers used for?

Duct dampers are used to regulate and control the flow of air through the ductwork. They can adjust the volume of air delivered to different areas or rooms, allowing for customized temperature control and improved system efficiency. Dampers can be manual, requiring physical adjustment, or automatic, which can be controlled remotely or through a building management system.

Can mold grow in my ducts?

Yes, mold can grow in ductwork under the right conditions, especially if there is moisture from leaks, condensation, or high humidity levels. Regular inspections, proper sealing, and maintaining a dry environment within the ducts are critical to preventing mold growth.

What are the health risks associated with dirty ducts?

Dirty ducts can circulate dust, pollen, pet dander, mold spores, and other airborne contaminants throughout your home, potentially exacerbating allergies, asthma, and other respiratory conditions. Regular cleaning and maintenance of the ductwork can help improve indoor air quality and reduce health risks.

Is it safe to have exposed ductwork in my home?

Exposed ductwork can be safe and is often used as a design feature in modern and industrial-style homes. However, it's essential to ensure the ductwork is properly sealed and insulated, especially if it runs through unconditioned spaces, to maintain efficiency and comfort. Exposed metal ducts should be regularly inspected for signs of condensation, rust, or damage.

Can I paint my ductwork?

Yes, you can paint ductwork, but it's important to use the right type of paint to avoid emitting harmful fumes and ensure it adheres properly to the duct material. For metal ducts, use a high-quality, heat-resistant paint and ensure the surface is clean and free from rust or grease before painting. For fiberglass duct board or flexible ducts, consult with a professional, as painting these materials may not be advisable.

What are the signs of a ductwork problem?

Signs of ductwork problems include uneven heating or cooling, higher than usual energy bills, visible dust or mold around vents, strange noises like rattling or whistling, and persistent odors. If you notice any of these issues, it's advisable to have your ductwork inspected by a professional to identify and address the problem promptly.

How can I extend the lifespan of my ductwork?

Regular maintenance, including cleaning, inspecting for leaks and damage, and promptly repairing any issues, can significantly extend the lifespan of your ductwork. Ensuring your HVAC system is properly sized and your home is adequately insulated can also reduce the strain on your ductwork, contributing to its longevity.

What are the latest trends in ductwork technology?

Recent trends in ductwork technology focus on improving energy efficiency, air quality, and installation ease. Innovations include antimicrobial coatings to prevent mold growth, advanced sealing materials for better airtightness, and smart duct systems integrated with home automation for precise airflow control. Materials that offer better insulation and durability are also being developed, reducing energy loss and extending the system's life.

What are some energy-saving tips for ductwork?

To save energy with your ductwork, ensure all connections are properly sealed to prevent air leaks. Adding insulation to ducts in unconditioned spaces can significantly reduce heat loss or gain. Regularly cleaning and maintaining the ductwork and HVAC system can also improve efficiency by ensuring optimal airflow. Upgrading to a duct system designed for energy efficiency, including the use of automated dampers and zoning controls, can further reduce energy consumption.

What are some resources for learning more about ductwork?

For those looking to deepen their understanding of ductwork, resources such as the National Air Duct Cleaners Association (NADCA), the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE), and the U.S. Department of Energy offer extensive information on ductwork standards, maintenance, and energy efficiency practices.

HVAC trade publications and online forums can also provide valuable insights and updates on the latest trends and innovations in the field.

What are the latest trends in ductwork technology?

What are some fun facts about ductwork?

Ductwork has been an essential part of human-built environments for centuries. Ancient Romans used ductwork in their hypocaust systems to heat baths and buildings. The Philadelphia Mint, built in 1792, had a central air conditioning system that included ductwork to remove smoke and dust. Today, innovative ductwork materials and designs are used in cutting-edge architecture to both heat and cool buildings efficiently and aesthetically.

How can I make my ductwork more aesthetically pleasing?

Exposed ductwork can be integrated into a home's design to add an industrial or modern touch. Painting ducts to match the room's color scheme or using decorative wraps can help them blend in or stand out as a feature. Additionally, creative routing of ductwork, such as incorporating it into architectural elements, can turn a functional necessity into a design asset.

Do I need to get a permit for ductwork installation or repair?

Permit requirements for ductwork installation or repair vary by location. In many cases, a permit may be required to ensure that the work complies with local building codes and standards, particularly for significant modifications or new installations. Always check with your local building department or consult a professional HVAC contractor to understand the permitting requirements in your area.

What are some DIY tasks I can do for ductwork maintenance?

Homeowners can perform basic ductwork maintenance tasks such as inspecting ducts for visible damage or leaks, cleaning vent covers, and changing air filters regularly to maintain airflow and air quality. Sealing minor leaks with duct mastic or foil tape can also be a manageable DIY task. However, more complex repairs or installations should be handled by professionals.

What are some common mistakes to avoid with ductwork?

Common ductwork mistakes include ignoring leaks or damage, which can lead to inefficiency and higher energy costs; using duct tape for repairs, which can degrade over time; neglecting regular maintenance and cleaning, leading to poor air quality; and DIY installations or repairs without adequate knowledge, potentially resulting in improper sizing or unsafe conditions. Prioritizing professional advice and services when needed can help avoid these pitfalls.

This guide has endeavored to provide a comprehensive overview, equipping you with the knowledge to make informed decisions whether you're installing a new system, upgrading an existing one, or simply aiming to understand the mechanics behind your home's heating and cooling.

By embracing the principles of effective ductwork design, prioritizing air quality and fire safety, and leveraging innovations in smart home integration, you can achieve a balance of comfort, efficiency, and sustainability. Remember, optimizing your HVAC system is ongoing, with continuous advancements in technology offering new opportunities for improvement. Stay informed, consult with professionals, and never underestimate the impact of well-designed and maintained ductwork on your living or working environment.

and now, NASCAR Racing Sponsor

and now, NASCAR Racing Sponsor